Manufacturing Engineering

Manufacturing Excellence Through Engineering Expertise

We provide end-to-end manufacturing engineering services that turn designs into production-ready solutions with precision, efficiency, and reliability. Our expertise covers process development, tooling, machining, quality validation, and mass-production readiness. Every solution is engineered to deliver consistent performance on the shop floor.

Process Engineering & Planning

We create optimized workflows, cycle-time planning, and machining strategies to ensure smooth, cost-effective production.

Tooling & Fixture Development

From BIW fixtures to machining & inspection fixtures, we design robust tooling that ensures accuracy, repeatability, and long-term durability.

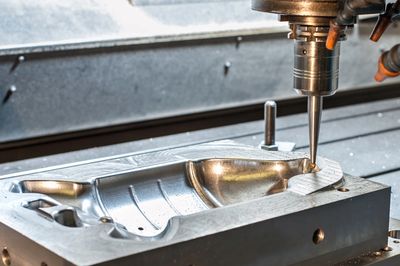

CNC & VMC Batch Production

We support CNC and VMC batch production with precision setups, optimized tool paths, stable fixtures, and proven machining parameters for consistent part quality.

Prototype Prove-Out

Our team executes prototype machining, trials, and validations to finalize the manufacturability and performance of new components before production.

Mass Production Support

We develop scalable manufacturing solutions for high-volume production, including fixture design, process optimization, and automation integration.

Manufacturability (DFM) Optimization

Designs are refined to minimize machining time, reduce material waste, and improve overall manufacturability without compromising quality.

Quality & Validation

Every process is validated through cutting trials, CMM inspection reports, and dimensional checks to meet industry and customer standards.

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.